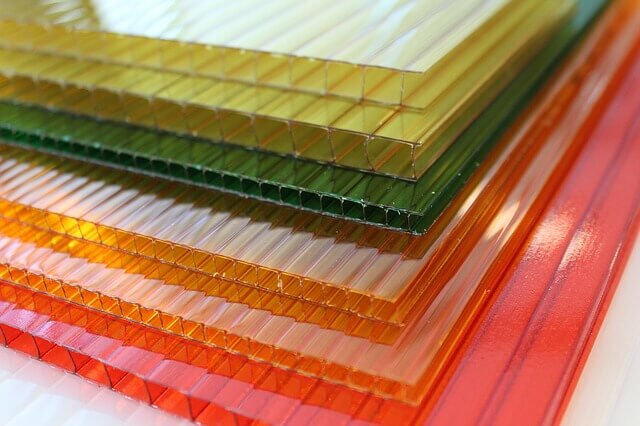

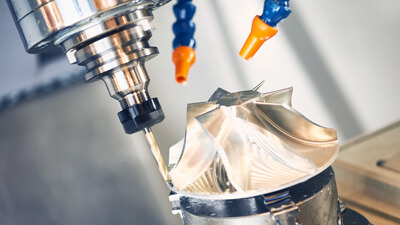

Polycarbonate is a transparent, impact resistant and durable material. It's often used for protective equipment and as a cheaper and lighter substitute for glass. Polycarbonates are easily molded, thermo-formed and are easily worked with. It is often used for 3D printing, CNC machining, injection molding and other types of manufacturing methods.

Order in Polycarbonate

| Property | Value |

|---|---|

| Service temperature | −40 °C (−40 °F) and 80 °C (176 °F) |

| Density | 1.20–1.22 g/cm³ |

| Tensile Strength | 59 MPa (8,500 PSI) |

| Flexural Strength | 93 MPa (13,500 PSI) |

| Elongation (ε) at break | 80–150% |

| Young's modulus (E) | 2.0–2.4 GPa |

Polycarbonate (PC) is an impact resistant, durable plastic that has flame-retardant properties. This material is often used when impact resistance and/or transparency are a product requirement (for instance, bullet-proof glass). PC is commonly used for plastic lenses in eye wear, in medical devices, automotive components, protective gear, greenhouses, and cases for CDs, DVDs and Blu-ray disks. PC has very good heat resistance and can undergo large plastic deformations without cracking or breaking. As with other thermoplastics, it can be heated to its melting point, cooled, and reheated again without significant degradation. Polycarbonate is often used for subtractive machining processes on a mill or lathe. Machined parts may require some post processing to remove tool marks and to restore the transparent nature of the material. Besides, PC is used as a material for FDM 3D printing.

Some types of bulletproof glass are made from layers of glass laminated together with a layer of Polycarbonate in between. This material enables making the glass transparent and lightweight but strong enough to handle some damage.

Polycarbonate can be injection molded in its pure form or with additives such as glass fibers. Since the material is amorphous, higher molding temperatures can decrease its mechanical properties.

Cover image by Design Iniative

All Comments (0)