Plywood is a type of engineered wood from the family of manufactured boards. It consists of thin layers of wood veneer with resin adhesive between them. The wood grain in this material is placed at a 90 degrees angle to one another improving wood’s dimensional stability and properties.

Order in Plywood

| Property | Value |

|---|---|

| Core Thickness | 12 mm |

| Average Density | 500 KG per/m3 |

| Moisture Content | 8-13% |

Plywood is manufactured from wood veneers glued together. Wood grains a plywood consists of are rotated at a 90-degree angle towards one another to provide strength to the material.

Some subtypes of plywoods are called long-grain. These materials stand out due to the grain of the outermost plies that are parallel or nearly parallel to the long edge of a panel. Another subtype can be described as cross-grained plywood - in which the grain of the outermost plies is parallel or nearly parallel to the short edge of the panel.

Plywood can be classified into several categories:

Other types of plywood include special versions for aircraft and marine applications as well as decorative ones. Plywoods also have a grade mark to indicate the quality of material and its structure.

One of the most notable advantages of plywoods is that there is a huge variety in terms of thickness and dimensions of panels. Though the material loses to normal woods in terms of stiffness, it is much more affordable and easy to work with simply due to the large size panels available. This allows construction workers to have fewer cuts of material and build structures much faster (in comparison to ordinary wood).

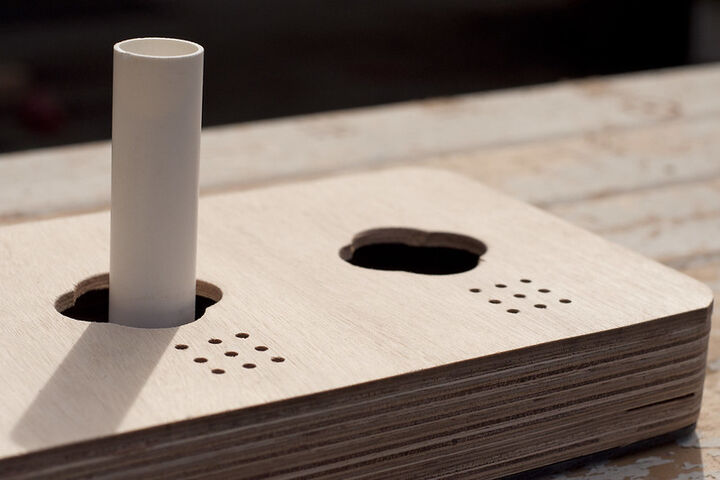

Plywood is easy to CNC machine and mill on routers, cutters, and milling centers. It doesn’t exhibit any special difficulties during the process aside from the common need to remove wood particles in the process when working on bigger pieces.

Machined plywood is used in all the same industries, where cut or milled parts are needed. It is possible to process it to high precision and accuracy without damaging the surface. Thanks to its relatively low costs (compared to solid wood), plywood is used for small projects and hobbies, run on simple desktop carving and milling routers.

Plywood is simple to laser cut and engrave. Its heat-affected zone is low, so the workpiece doesn’t deform during the process. Naturally, burned marks occur in contact points, which is also used as a design choice for some engraved pieces.

Plywood appears quite strong by itself, however, for some structures, it requires extra reinforcement. This can be made in a form of adding structure on the edges or ribs underneath the plywood panel, which will support the material.

From the composition side, plywood can be reinforced with a fiberglass outer shell. For the best result, plywood is used as a core, while fiberglass is lined on both sides.

Plywood is much stronger than chipboard or MDF due to the cross-grain orientation of the fibers in it.

All Comments (1)